Threshing Wheat

By happenstance the Mahrt family archive includes a picture of a threshing machine complete with a detailed caption. The threshing machine was owned by the Mahrt brothers, John and Fred, and was one of the first threshing machines in the Reardan area. The brothers disbanded their partnership after a bumper crop in 1897 which ended in November snows. This threshing machine could well have been the same threshing machine and the same scene as the 1896 Buckman murder. The following description is adapted from those dictated by William F. Mahrt to Leah Marht in 1978 to show how complex and manually intensive harvest was back then (and how there were six witnesses to the John Buckman Murder). He also notes that the picture may have been taken on the Buckman place as it was less hilly that the Mahrt land.

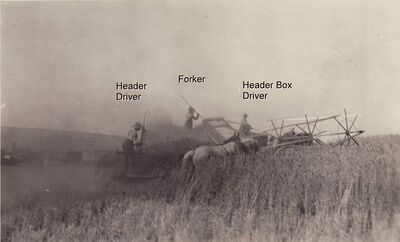

Wheat was cut with a reaper or with a header pushed by six horses. The wheat would be cut by the teeth of a sickle moving back and forth, then a reel would lay the stalks down on the draper. The stalks with heads were then moved by the draper, a canvas conveyor belt, to a horse drawn header box, a special wagon with a short inside side rail and tall outside side rail. The header box was driven to the site of the threshing machine and the cut wheat stalks were unloaded with the aid of a Jackson Fork or by hand. The reaper or header is powered by its wheels using the power of horses to run the sickle, reel, and draper as well as to move it forward.

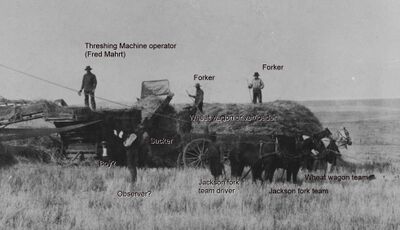

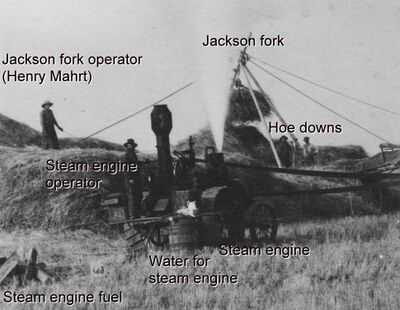

The “Jackson fork operator”, in this picture John and Fred’s younger brother, Henry, had the job of operating the Jackson Fork, to lift wheat stalks from the pile to the derrick table, and then to move the fork back to the pile. The horses are used to power the Jackson Fork.

On the derrick table are two men called “hoe downs” who use pitchforks with the tines turned down to move the wheat stalks onto the draper, a canvas conveyor belt that carries the stalks into the thresher.

Another man operated the steam engine that powers the thresher. He wanted a big enough fire to make steam to power the thresher and not so big that the boiler explodes. This steam engine burned wood as fuel as seen on the far left. The steam engine was only used to power the thresher, but not to move it. The thresher was moved with horses.

Fred Mahrt is standing on top of the thresher. His job is to operate the thresher by making sure that the wheat stalks are fed into the machine evenly. The grains of wheat are flailed out of the heads by the teeth on a rotating cylinder. The wheat kernels are then separated from the straw and the chaff through a set of zinc sieves with holes in them for the wheat to fall through. A blower blew the straw and chaff into a pile behind the thresher. Forkers would assist in piling the straw and chaff. The straw and chaff would be left in the field to feed cattle during the winter.

On the front side of the thresher, a man would collect the wheat in sacks and pass the filled sacks to a loader. The loader would load the sacks into a wagon and drive the wagon to the barn or to a warehouse in town. If the wheat was handled in bulk; the sacks would not be sown, but left open so they could be easily dumped at their destination.